Comparing Energy Recovery Devices: HPB Turbochargers vs Pelton Wheels

There are many benefits of replacing a Pelton Impulse Turbine with a Hydraulic Pressure Booster or HPB, with energy savings realized in the range of 6-20%.

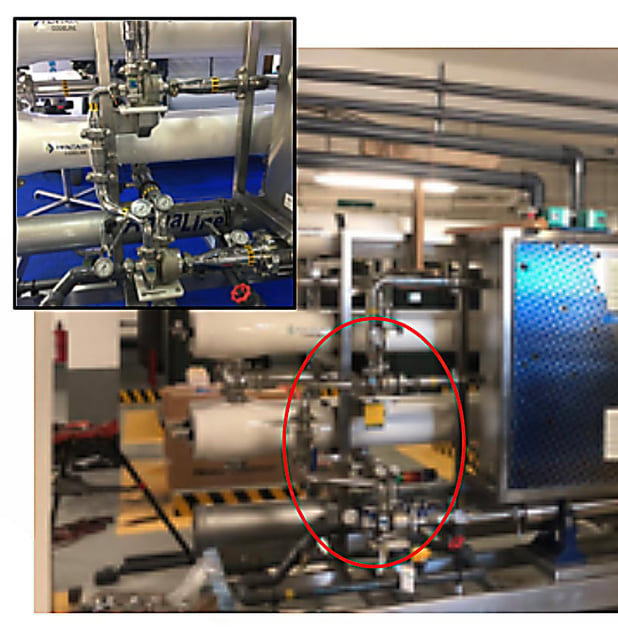

Total costs of HPB are typically 50% less than the cost of the Pelton Impulse Turbine. The HPB is much more compact and lower weight resulting in easier installation and maintenance.

This paper compares the cost factors of the Hydraulic Pressure Booster (HPB) energy recovery device manufactured by Fluid Equipment Development Company (FEDCO) with the Pelton Impulse Turbine (PIT) in seawater reverse osmosis (SWRO) applications

Executive Summary

- Energy savings from 6% to 20%

- Total cost typically 50% less than the cost of the PIT system

- More compact and lower weight

- Ease of installation

- More reliable and easier to maintain

Related Articles

Introducing the BiTurbo: a Revolution in RO Technology

The next generation of desalination will rely on multi-stage, high recovery reverse osmosis, delivering a lower cost of water and improving membrane performance.

MSMT - A Significant Process Improvement for SWRO

Executive Summary Seawater reverse osmosis systems (SWRO) are the mainstay of large-scale desalination systems. Plant designs have settled in a more or less standard configuration using a single membrane stage with permeate recoveries ranging from

ERD Efficiency: What System Builders and Consultants Need to Know

Executive Summary This White Paper addresses the impact of ERDs on the energy consumption of the RO process using an objective and fully transparent criteria. The analysis shows that published ERD efficiency data has virtually no correlation to the