Efficiency designs the flow path. Flowing lines and smooth contours help the MSD to be the most efficient centrifugal pump on the market.

Maximizing Material Efficiency

Sophisticated casting processes allow optimal usage of material; no added material if not needed and ample material where needed.

Computational Fluid Dynamics (CFD)

Today, CFD is widely used for fluid machine design. However, it takes hundreds of tests to fine-tune and validate the results. MSD pump tests number in the hundreds during development.

Dealing with Thrust

Hydraulically induced axial thrust can exceed 15,000 pounds of force.

Ring Section Pump

Ring Section Pump Cross Section

- Axial thrust increases potential for shaft bending or bowing

- Increases potential for rubs with shaft bearings and impeller wear rings

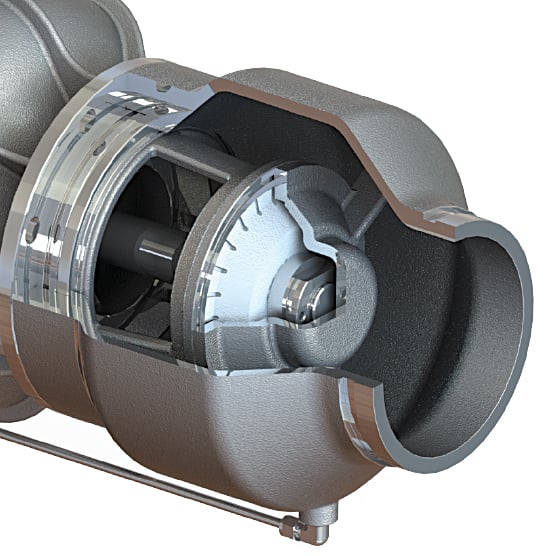

MSD HP Pump

Shaft in Compression - FEDCO Design

MSD Series Pump: Patented Water Bearing

- Axial thrust causes shaft to become straighter

- Straighter shaft reduces rubbing against shaft journal bearings

- WATER BEARING™ places the shaft in tension

Related Articles

MSMT - A Significant Process Improvement for SWRO

Executive Summary Seawater reverse osmosis systems (SWRO) are the mainstay of large-scale desalination systems. Plant designs have settled in a more or less standard configuration using a single membrane stage with permeate recoveries ranging from

Reverse Osmosis Pumps and ERDs: Making the Right Choice for Offshore Platforms and Marine Service

Executive Summary Reverse Osmosis (RO) systems are widely accepted on offshore platforms and vessels.These marine applications require compact size, good efficiency and low weight and the utmost in reliability as a failure can result in large

What is the Water Bearing™ technology?

What is Water BearingTM technology The Water Bearing™ technology was developed for all FEDCO pumps to increase reliability and maintenance for reverse osmosis systems. The patented FEDCO Water Bearing™ uses the pump discharge pressure to produce a